1 mw diesel generator

Product Parameters

1 mw diesel generator

Model

AXQ-210A

Welding Method

Manual Arc Welding / TIG Welding

No-load Voltage (V)

70-75

Load Voltage (V)

22-30

Welding Current (A)

50-210

Duty Cycle

60%

Electrode Range (mm)

1.6-4.0

Power Type

Single-cylinder, Four-stroke, Air-cooled Gasoline Engine

Power (hp)

15

Displacement (cc)

420

Bore × Stroke (mm)

90 × 66

Fuel Tank Capacity (L)

25

Starting Method

Electric Start

Rated Voltage (V)

220

Rated Frequency (Hz)

50

Rated Power (kW)

3.0

Power Factor

1.0

Key Features

Packaging and Delivery

- Use sturdy packaging materials, such as heavy-duty corrugated cardboard, foam padding, and reinforced plastics, to protect against impacts, moisture, and dust.

- For large or high-value generators, use wooden crates or customized containers to provide comprehensive protection.

- Use cushioning materials (such as foam and bubble wrap) to provide additional protection for sensitive components like control panels and electronic systems.

- Secure or package separately any loose parts (such as detachable covers and exhaust systems).

- Place desiccants inside the packaging to prevent moisture damage to the equipment.

- Use sufficient cushioning materials to reduce vibrations during transportation.

- Clearly indicate the destination address, handling instructions (such as “Handle with Care” and “Moisture-Proof”), and any hazardous material warnings on the packaging.

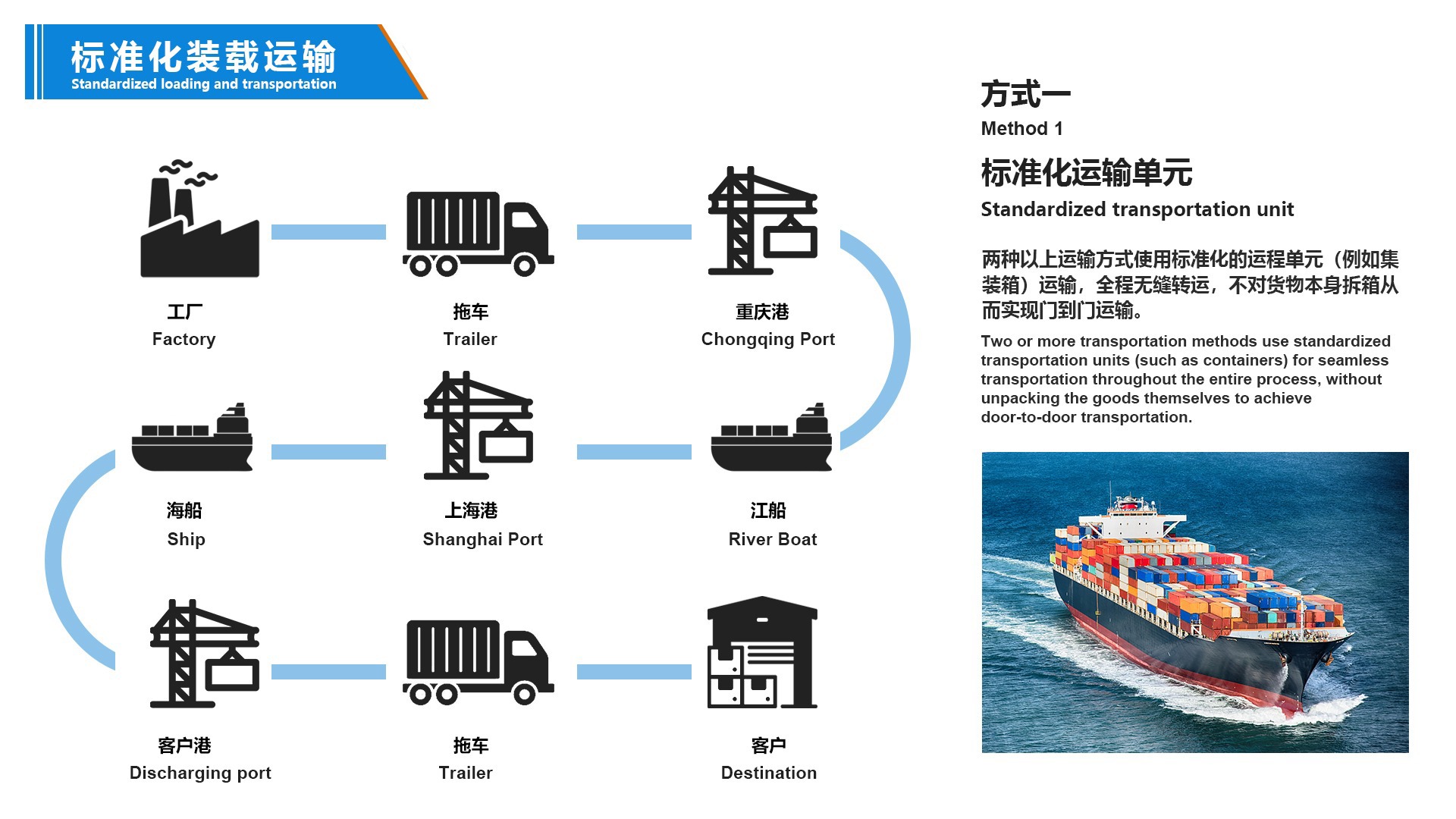

Securing the Equipment

- Diesel generators must be firmly secured during transport to prevent movement due to bumps or sudden braking.

- Use steel straps, chains, or specialized securing devices to ensure stability.

- Select an appropriate transport method based on the generator’s size, weight, and destination, such as road transport, sea freight, or air freight.

- For sea transport, it is recommended to use containerized shipping to ensure the equipment is securely fastened inside the ship’s hold.

- Minimize exposure to high temperatures, low temperatures, or humid environments.

- Provide additional waterproofing and wind protection for the equipment under adverse weather conditions.

- When unloading with a forklift or crane, ensure the forks are wide enough to support the generator’s base.

- Place the equipment on a flat surface during unloading, avoiding tilt angles exceeding 30 degrees.

- Ensure that the transport process complies with the regulatory requirements of the destination country, including customs and environmental standards.

- Prepare complete transport documents, such as commercial invoices, packing lists, and certificates of origin.

Baolitong Generator Production & Testing Equipment List

— Ensuring Quality with Precision Equipment, Defining Reliability with Data

1. Material & Component Testing Equipment

Spectrometer (SPECTRO, Germany)

Coordinate Measuring Machine (CMM) (Mitutoyo, Japan)

X-ray Flaw Detector (GE, USA)

2. In-Process Inspection Equipment

CNC On-Machine Inspection System (HEIDENHAIN, Germany)

Roundness & Cylindricity Tester (Taylor Hobson, UK)

Surface Roughness Tester (KOSAKA, Japan)

3. Assembly & Performance Testing Equipment

Intelligent Torque Wrench (STANLEY, USA)

Automatic Leakage Detector (COSMO, Japan)

Dynamometer System (SCHENCK, Germany)

Power Quality Analyzer (Fluke, USA)

4. Environmental & Reliability Testing Equipment

High-Low Temperature & Humidity Chamber (KSON, Taiwan)

Vibration Testing System (LDS, USA)

Salt Spray Test Chamber (ESPEC, Japan)

High-Altitude Simulation Chamber (Custom Equipment)

5. Electrical Safety Testing Equipment

Insulation Resistance Tester (HIOKI, Japan)

Ground Resistance Tester (GMC-I, Germany)

EMC Electromagnetic Compatibility Testing System (EMTEST, Switzerland)

6. Digitalization & Traceability Systems

Laser QR Code Marking Machine (Videojet, USA)

MES Manufacturing Execution System (SIEMENS, Germany)

Company Profile

As one of China’s Top 50 General Gasoline Engine Enterprises, Chongqing Baolitong has experienced over a decade of rapid growth, evolving into a comprehensive power solutions provider that integrates R&D, intelligent manufacturing, sales, and services. With Chongqing as our headquarters, we have expanded globally, establishing a full industry-chain layout that covers research, production, marketing, and customer service, positioning ourselves as a leader in the industry.

1. Intelligent Manufacturing Base: Industry-Leading Production Capacity

We operate an 80,000+ m² smart manufacturing facility, equipped with cutting-edge precision machining equipment, fully automated assembly lines, and digital testing systems. Our annual production capacity exceeds 1 million units, setting a new benchmark in the industry.

2. R&D Team: Innovation Driven by Industry-Academia Collaboration

Our company boasts a team of over 200 senior technical experts and has established a national-level laboratory and a provincial engineering technology center. We collaborate with multiple universities and research institutions through joint innovation platforms. To date, we have secured 150 national patents, 50 core technology certifications, and led the formulation of three industry standards.

3. Global Market Network: Expanding with Strategic Depth

We have established 30+ provincial sales and service centers across China, with our products exported to 50+ countries and regions, serving over 1 million customers worldwide. Our annual export volume continues to grow at an average rate of 25%, positioning us as a benchmark brand in the "Belt and Road" energy equipment sector.

4. Ecosystem Collaboration: Full Industry Chain Synergy

We have built strategic alliances with over 200 global suppliers, ensuring an efficient and stable supply chain. Additionally, we work with 500+ channel partners, fostering an ecosystem of shared technology and market expansion to drive mutual success.

Chongqing Baolitong – Powering the Future with Innovation and Excellence!

Certificate

F A Q

1. How can I place an order with Baolitong?

You can place an order through our official website or by contacting our sales team via email or phone. Our team is ready to assist you throughout the ordering process.

2. What is the lead time for international orders?

International orders generally have a lead time of 2-4 weeks, depending on order specifications and customization requirements. We prioritize efficient processing to ensure timely delivery.

3. Do you offer bulk discounts for large orders?

Yes, we provide competitive pricing and bulk discounts. Contact our sales team with your order details, and we’ll offer a customized pricing plan.

4. How do you manage international shipping and customs?

We collaborate with trusted international logistics providers to ensure secure and timely delivery. Additionally, we assist with customs clearance and provide all necessary shipping documentation for a hassle-free experience.

5. Can I track my shipment after placing an order?

Yes, once your order is shipped, we will provide tracking information so you can monitor the delivery status in real time.